Mhlawakhe Vatsha

Privat

Privat

Scholarship holder Mhlawakhe Vatsha

"I completed my master's degree in engineering at the University of Witwatersrand, Johannesburg, and am a recipient of the Helmut & Babs Amos Scholarship from the DAAD-Stiftung. Among other things, the scholarship helped me to buy certain equipment that I needed for my work.”.

Supported by the Helmut & Babs Amos Scholarship, Mhlawakhe Vatsha studied at the University of Witwatersrand. His degree focused on the development of flammable and environmentally friendly building materials made from fine coal.

In the following, he shares his personal experiences during his studies and gives insights into the knowledge he gained:

The flammability test of the coal composites was conducted to determine their ability to resist fire as we know that coal is highly flammable. It could be satisfying to the construction industry to prove that coal composites would not pose any fire hazards when utilized. The coal fines and coal tar were received and analyzed for their properties. After analysis coal tar was modified by air-blowing method to release volatile matters and transform it to low volatile anisotropic coal tar pitch that can be used as a binder for coal structural composites.

My research involved using coal fines, coal tar pitch, and dimethylpolysiloxane to produce coal composites for building applications. The as received coal discards were firstly dried into the sun to release moisture.

Thereafter it was crushed and split to get the representative samples. Coal tar was received and modified by air-blowing method to release volatile matters and convert aliphatic hydrocarbons to aromatic hydrocarbons. The materials (coal fines, coal tar, and coal tar pitch) were analysed to understand their properties. The composites’ properties proved that the produced composites surpass the standard for building materials. The composites produced with 30% coal tar pitch as a binder showed extreme compression, and flexural strength when compared with conventional building materials.

Privat

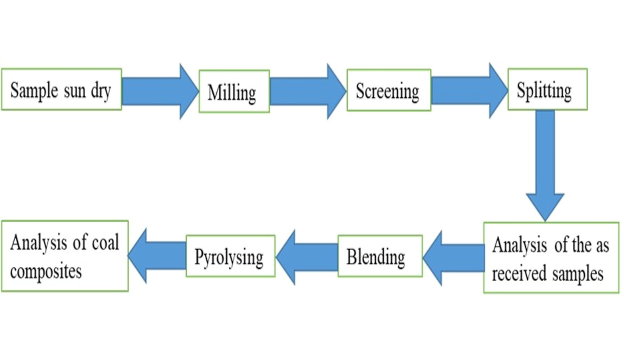

Figure 1: Process flow diagram for production of coal composites

Coal tar pitch from air-blowing, and dimethylpolysiloxane were used as the binders for coal fines, respectively. The coal fines were mixed with each binder at different proportions, molded, cured in an oven, pyrolysed in a furnace and the resulting composites were analysed for their properties to determine if they meet the standard for the building materials. The process flow diagram of producing coal composites is shown in Figure 1.

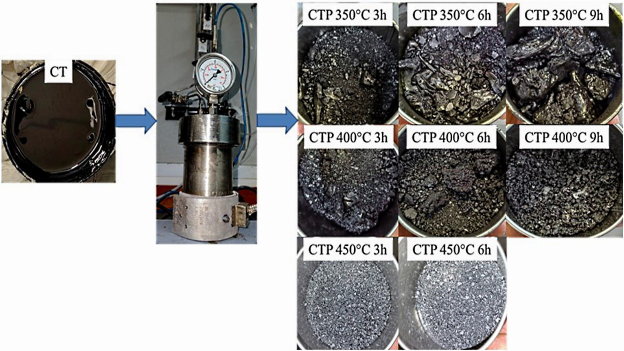

The coal tar air-blowing was conducted in a stainless steel 1-liter thermal reactor where coal tar (CT) was fed in a reactor and heated at different reaction temperatures and times as stipulated in Figure 2.

The produced coal tar pitches (CTPs) were analysed for volatile matter content, functional groups, H/C ratio, mesophase content and aromaticity. Figure 3 shows when I was in the lab running thermogravimetric analysis (TGA) of the samples.

Privat

Figure 2: Produced coal tar pitches

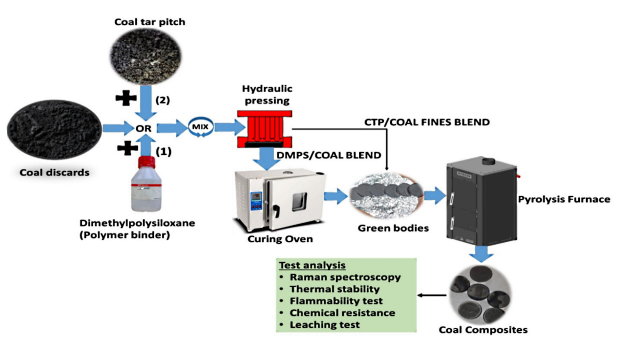

After analysing as received samples and producing coal tar pitch the process of producing coal composites was commenced. The coal fines and coal tar pitch were mixed, compacted, cured, and pyrolyzed using a furnace as shown in Figure 4. The resulted mixture showed more compacted solid structure after it was pressed, and the mixture became lighter in weight.

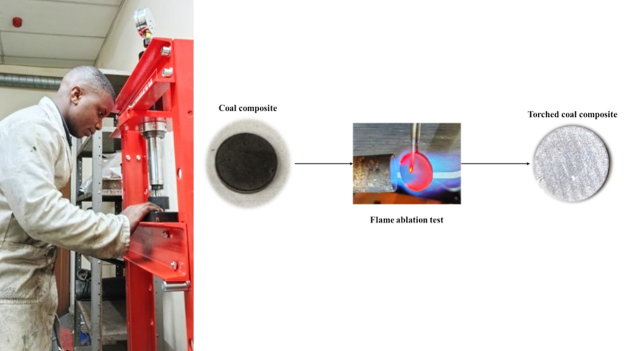

I spent hours in the laboratory producing these composites, as I was producing them at different conditions in order to get the best parameters that would be used to produce them. Figure 5 shows when I was fabricating the composites using hydraulic pressing machine. I also attended many webinars hosted by the department of chemical and metallurgy and faculty of engineering.

In order for me to relax I attended music or entertainment events hosted by the university and also external events. Sometimes during the weekend, I would go for games with friends but that was not a causality as I was busy and occupied by the research work.

Privat

Figure 3: Analysing samples using TGA

The produced coal composites were analyzed for physicochemical, mechanical, and microstructural properties. The composites were also tested for flammability to determine if they could not be fire hazardous since they were produced from flammable materials such as coal and coal tar pitch.

The results showed that the composites are not highly flammable. The flammability test was conducted using butane oxy acetylene torch at 1300°C (Figure 6). In addition, the composites were also analyzed for the environmental friendliness by determining the leaching concentration of the trace and heavy elements. The leaching results showed that composites can be used without posing hazards into the environment as they showed low risk leaching concentration of trace and heavy elements.

Privat

Figure 4: Fabrication process of coal composites

The research work was also presented at the University of the Witwatersrand, faculty of engineering and built environment inaugural seminar and it won the 3rd poster presentation prize refer to Figure 7. The award was presented by the dean of faculty of engineering and built environment Prof. T Majozi (right) and assistant dean for research and innovation Prof. G Simate (left).

I would like to take this opportunity to thank DAAD-Stiftung and send my sincere gratitude to Mr. Amos for assisting me with the scholarship for my research. The scholarship assisted me to buy some specific equipment needed for my work, like I was able to buy an automatic hydraulic press, molds, and the reactor and I was also able to send my samples for testing to other institutions to assist me test the samples using their equipment that is not available in our facility.

Privat

Figure 5: Compacting coal composites using a hydraulic machine and Figure 6: Flammability test of the coal composites

I was able to pay my tuition and research fees without fail as I have completed my research project without owing the institution any fees.

It is normal for students to finish with outstanding fees and in my case I was able to finish with all my fees paid off. The financial support I have received from your magnificent institution made me to realize a dream of completing master’s degree in engineering without any financial struggles.

Privat

Figure 7: Award for 3rd position poster presentation

The research was submitted in November 2023 for examination and the dissertation feedback was sent back to me in February 2023, where there were minor corrections to be done on the master’s dissertation and it was sent back for final submission April 2024.

Now I am proud to say the dissertation has been submitted for consideration and I will let you know when the outcome letter has been sent to me. In addition, the journal is also sent to the publishers, and I will also send it to you once it has been accepted and published.

As of April 2024.